|

|

|

An Apparatus to Aid in Surveying High Walls

Harrison Eiteljorg, IIFor almost four years the CSA Propylaea Project has been working to find a successful solution to its surveying needs.1 Desktop photogrammetry and 3D scanning were tried since both technologies permit surveying without actually climbing on the walls, and a heavy, bulky machine called a man-lift was used to lift people next to the walls safely. Neither desktop photogrammetry nor 3D scanning provided the solutions needed. Data from scanning was not sufficiently precise, and desktop photogrammetry requires that any surveyed data point in one photo be clearly identifiable in other photos; that seems simple but is not. Unless a point is marked by some color change or shadow's edge, it simply will not be identifiable in two photographs from different vantage points.2

The man-lift worked in the sense that it enabled the tried-and-true surveying process of using a total station to survey targets held by members of the survey team in properly selected places. (Selecting the data points from a distance was found to be problematic early in the history of the project.) However, the man-lift could not get safely into corners or other difficult areas because of the weight and relatively large footprint of the machine itself. In addition, working high on the walls was very uncomfortable because of the lack of stability of the machine.3

Several possibilities for using remotely-controlled or semi-remotely-controlled devices on the walls were considered, and engineers were consulted to assist. These approaches seemed to offer some promise, but all required more engineering sophistication and expense than the project could afford or justify. Various experiments with PVC piping and aluminum posts as uprights to support equipment offered ample evidence of the problems to be expected. (Injuries sustained in the experimentation processes were all very minor; moments of unexpected humor were frequent.)

By chance a commercial product used for mid-sized construction projects was seen in use and ultimately found to offer just the right mix of capabilities. This is a form of light-weight, portable scaffolding that can be raised, taken down, moved, and adjusted with relative ease and that offers the possibility of getting people up and next to the walls where they can hold survey targets in place without the bulk, the weight, or the expense of the man-lift. Its primary commercial use seems to be for putting siding or stucco on building exteriors. 4

As designed, the equipment could not be used on an ancient building without some modifications to its attachment system; it took some time to develop a way to hold the scaffolding to the walls of the Propylaea without risking harm to the ancient surfaces. CSA Propylaea Project participants both in Bryn Mawr and in Athens (especially Susan Jones and Manolis Kapokakis), an engineering student from Temple (Julio Vazquez), members of the CSA board, long-time friend and colleague Phoebe Sheftel, and Brett Thomas all helped to refine the system that was finally tested and found to be effective. Multiple experiments were conducted using pulleys, winches, and various other aids. In the end, a specific set-up was recommended as workable, and the permission of the authorities in Athens to try this approach was granted. (Testing involved a variety of experiments, once again with no serious injuries but several moments of levity.) The experiments were made possible in part by the generosity of the manufacturer, Alum-A-Pole, Inc., which donated the necessary equipment to the project. The project team is very grateful to the company.

The equipment was shipped to Athens, and it was tested at the beginning of December. This was not intended to be a survey session but a proof-of-concept experiment to show that people could position themselves next to the walls with the necessary precision and safety to carry out surveying work. The experiment was a success, and, thanks to various comments made by the Athenian participants in the project; Tasos Tanoulas, Manolis Kapokakis, and Mary Ioannidou; the set-up was made more generic. It may now be useful not only throughout the Propylaea but on walls or buildings in other places where quick, inexpensive access to high walls is required. That required some changes to the method for hoisting the assembled posts and securing them in place during work.

It remains to design, test, and implement a few added items and processes so that the system will work reliably and easily in its new configuration. That additional testing has begun and should be complete by the end of February. A further report will follow.

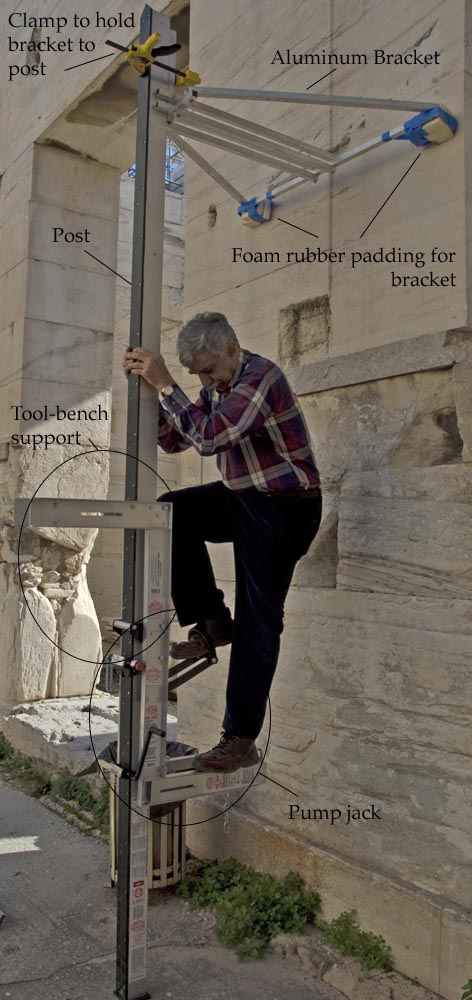

A brief description of the system follows here, with photographs to illustrate.

The Alum-A-Pole system starts with aluminum poles, each about 3 inches square and hollow; each can accept a slide-in attachment piece at either end so that the basic poles can be extended by adding one to another more or less indefinitely. Poles are available in a variety of lengths. (The basic poles act as sleeves around the slide-in attachment pieces, which have spring-loaded pins to hold the parts in the proper positions relative to one another.) Two longer posts are created out of the appropriate number of constituent poles and attachment pieces to reach the necessary length for the project at hand. The two posts are then raised to vertical to hold a scaffolding platform between them. The scaffolding platform rests on two L-shaped pump jacks, one attached to each post. What makes the system especially useful is the fact that the pump jacks have been designed not only to fit onto the posts but to be pumped by foot action so as to raise themselves on the posts, making it possible for two people, one at each post, to raise the platform on which they are standing from the ground to the very top of the vertical posts, lifting it about 3 inches with each pump.5 A release permits the users to crank the pump jack and scaffold platform back down.

Atop the pump jack is another L-shaped piece normally used as a tool-bench support. For this work it held a safety bar instead.

In standard usage each post, once in a vertical position, is anchored to the wall with one or more pairs of strong metal arms affixed to the post with a sleeve-and-clamp system and bolted to the wall. From a theoretical standpoint the attachment is not necessary. Since virtually all the weight on the post forces it to lean on the wall, it is effectively like a ladder and could lean on the wall with no other support. However, the system as designed includes no legs or other protrusions to support the post as it leans on the wall. Instead, each post is firmly attached to the wall with the metal arms. The attachment arms satisfy safety considerations, both real and psychological, plus concerns about sideways stability of the posts; they also establish the positions of the posts relative to the wall on which they lean.

The attachment arms obviously did not meet the needs of the CSA Propylaea Project. Their initial replacements, used in experiments in the U.S., were a combination of two things: a bracket to rest against the wall, holding the post in its proper position and vertical alignment but not damaging the wall, and a rope from the top of the post to the house wall (planned to go over a Propylaea wall in Athens so it could be tied down at ground level on the other side of the wall). With the post in position and leaning on the bracket, it is quite possible to omit the rope, but the rope does add to the sense of security. In addition, it was used to help hoist the post into position and to control it while lowering it to the ground again at the completion of the work.

In Athens it was suggested that the rope would prevent using the apparatus in any setting with a ceiling or roof or, for that matter, anywhere with a delicate surface on the top of the wall. Therefore, it seemed a good idea to try to use props or braces to hold the post against the wall rather than the rope. The bracket was still required to provide the points on the wall against which each post would lean. (The rather large pieces of foam rubber padding used on the bracket arms in Athens, though, proved to be unnecessarily large, permitting more motion then desriable as they were compressed and allowed to expand by the shifting weight of the people on the scaffolding. Smaller pieces of foam will be used in the future.) It was not necessary to construct braces to replace the ropes in Athens because simple and effective ones were at hand -- in the form of two ladders. A ladder was placed against the post, and one of the workmen stood on each ladder to add weight, forcing the post more strongly against the wall. No rope was used, but the apparatus worked as it had in the U.S. (The rope was not needed to hoist the posts because a shorter post was being used -- 24 feet high rather than 30 feet high, as used in the original experiments. The seemingly small difference in length makes an enormous difference in the ease with which the post can be raised.)

Figure 1 shows the equipment set up in the U.S. with the bracket and rope; the author and Mr. Thomas are standing on the scaffold platform. The two upright posts were hoisted from their horizontal starting positions with the rope (yellow line visible in various places behind the upright posts) that led to fastening points inside the window frames in the dormers, en route passing through through pulleys to gain mechanical advantage; the ropes also held the posts securely against the wall once the posts were in position. The brackets provided buffers to prevent damage to the wall and to hold the posts the right distance from the wall. The brackets were specially made for this purpose. The platform, made of aluminum, was not sent to Athens; a wooden platform was used there. The plastic pipe serving as a safety bar in this image was not strong enough to be used seriously and was replaced by a galvanized pipe in Athens.

Figure 2 shows a single, 12-feet high pole set up in Athens to illustrate the dynamics of the system to our colleagues there. (Jeff Lamia, immediate past Treasurer of the Archaeological institute of America, is shown operating the pump jack. Mr. Lamia assisted with the experiment in Athens.) Note that there is nothing holding the post to the wall, only the bracket to keep it from damaging the wall. The weight distribution keeps the pole from falling. There is also no platform on the pump jack (being operated in the photo).

Figure 3 shows the double-post system in Athens, with the posts having been raised into position by Propylaea workmen (instead of using the rope) and with a ladder on each post (each weighted by a man standing on the ladder) to hold the posts against the wall as people work on the platform. Nothing else holds the posts in their vertical orientation save the weight distribution. This approach removes the need to pass a rope over the wall and makes it possible to use the equipment on any vertical wall without fear of accidental damage.

It took only a few minutes to set up the equipment and a few minutes more to pump the platform all the way up the wall. Cranking the platform back down and disassembling the equipment also required little time.

Fig. 1 - The apparatus set up in the U.S. with aluminum scaffold platform.

Fig. 2 - A single post, without supporting system or scaffold platform, in the NW wing of the Propylaea in Athens.

Fig. 3 - The apparatus set up in the NW wing of the Propylaea, with wooden scaffold platform, galvanized safety bar, and workmen on ladders to hold the posts against the wall.

Since returning to the CSA offices the author has been working on simple braces to be used in place of the ladders and simpler, more adjustable brackets to help position the post. As soon as additional Alum-A-Pole equipment has been obtained, project personnel and others will also work on the problem of raising a taller post without the use of ropes and pulleys.

-- Harrison Eiteljorg, II

1. We must survey individual points seven or more meters above the ground on the walls of the building and do so with the highest possible precision. Return to text.

2. In addition, even the simplest form of desktop photogrammetry requires, at the least, sufficient access to the walls to permit the placing of targets in all areas of interest. Stereo photogrammetry also requires access to the walls, but it is not dependent upon finding the same point in multiple independent photographs. Return to text.

3. For CSA Newsletter articles detailing these efforts, please see the section of the index with articles concerning the CSA Propylaea Project. Return to text.

4. The equipment is made in Scranton, PA; so it was possible to go to the corporate offices to get a better first-hand introduction to the equipment and its workings. Return to text.

5. One person could raise the platform alone, moving back and forth between the two posts to raise each side individually. This is possible but inefficient. Return to text.

For other Newsletter articles concerning The CSA Propylaea Project or the use of electronic media in the humanities, consult the Subject index.

Table of Contents for the Winter, 2008 issue of the CSA Newsletter (Vol. XX, no. 3)

Table of Contents for all CSA Newsletter issues on the Web

Table of Contents for all CSA Newsletter issues on the Web

| Propylaea Project Home Page |

CSA Home Page |